The latest innovation in H & B Mining’s conveyor transfer product range is the Speilbar (false deck) design. Comprehensive conveyor chute maintenance is essential for optimal material flow and containment, and ultimately mine productivity.

H & B Mining are well known for innovative conveyor transfer design within the Australian iron-ore community providing easy maintenance solutions for conveyor transfer points.

Cement Australia contacted H & B Mining following an internet search for conveyor diversion ploughs. Initial discussions outlined a need for a secondary circuit to divert excess water that had collected on the belt during the wet season prior to operation.

Hard working iron-ore mines in the Pilbara of Western Australia inherently require periodical upgrades at conveyor transfer points. H & B’s latest innovation, the STREAMLINE conveyor transfer design has been successfully installed across Pilbara mine-sites as part of conveyor transfer upgrades.

It was only a matter of time before the world market would stand up, take notice and embrace H & B Mining’s ‘Easy Maintenance’ product range which offers a safe, simple and speedy solution to conveyor transfer maintenance issues.

The overall success of the H & B Mining diversion plough caught the attention of VIGAN, an integrated engineering company based in Europe.

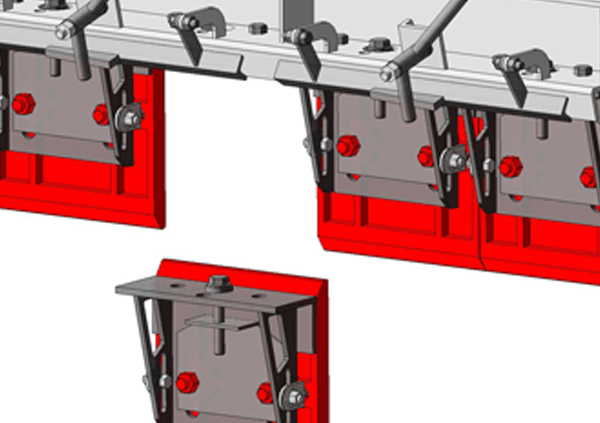

H & B Mining’s reputation for supplying easy maintenance segmented conveyor skirts attracted the attention of MMG Limited. Melbourne headquartered MMG Limited operate and develop copper, zinc and other base metals projects across Australia, the Democratic Republic of the Congo, Laos and Peru.

Following a recommendation from Australian headquartered engineering and project management consultancy Lycopodium, H & B Mining acquired their first contract from the African continent.

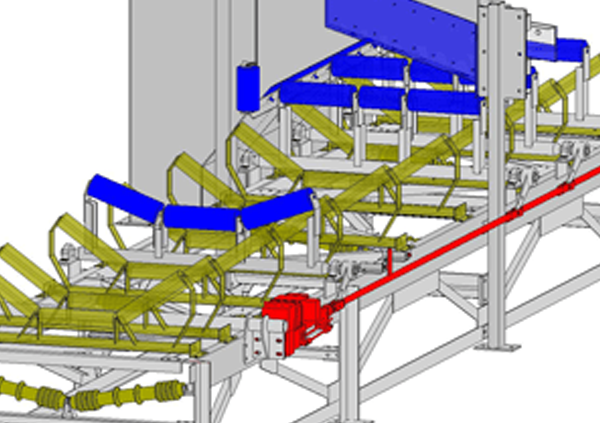

H & B Mining revolutionised impact idler design in the early 1990’s with the in Drop down retractable idler template image production of the ‘Drop Down Idler’ for mining conveyors.

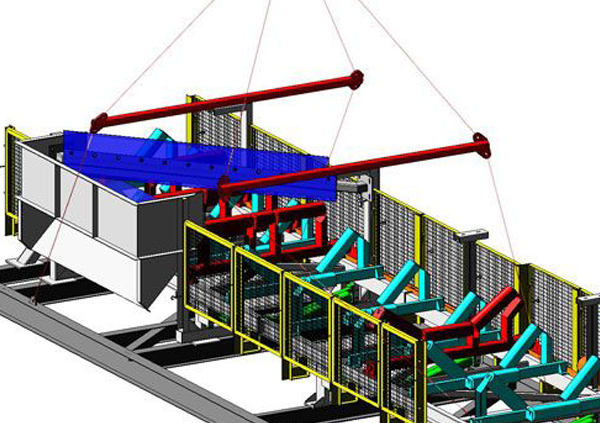

H & B Mining have just completed fabrication of a conveyor module which includes a carry belt diversion plough as an integral part of the design for Jimblebar Stage 2.