H & B MINING GO INTERNATIONAL IN 2016

It was only a matter of time before the world market would stand up, take notice and embrace H & B Mining’s ‘Easy Maintenance’ product range which offers a safe, simple and speedy solution to conveyor transfer maintenance issues.

2016 was a breakthrough year which saw H & B’s innovative easy maintenance skirt system and their equally impressive carry belt diversion plough employed outside of Australia.

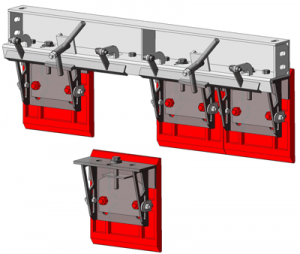

The first enquiry came from MMG who needed to find a solution to a number of troublesome conveyor transfer points at Kinsevere copper mine based in the Congo. Following a lengthy proposal and negotiation phase, it was decided to introduce H & B Mining’s ‘Easy Maintenance’ segmented skirt into the problematic transfer points. The purchase order was placed in July 2016 and the work was completed and shipped out to the Congo by October 2016.

The first enquiry came from MMG who needed to find a solution to a number of troublesome conveyor transfer points at Kinsevere copper mine based in the Congo. Following a lengthy proposal and negotiation phase, it was decided to introduce H & B Mining’s ‘Easy Maintenance’ segmented skirt into the problematic transfer points. The purchase order was placed in July 2016 and the work was completed and shipped out to the Congo by October 2016.

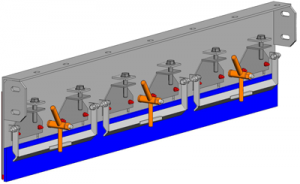

Not long after the initial enquiry from MMG, an enquiry came from Perseus Mining who also needed a solution for their troublesome transfers at Edikan gold mine in Ghana. A much simpler approval process followed as the client knew exactly which style of H & B conveyor skirt was needed to do the job. It was decided to incorporate a standard design EMS conveyor skirt previously used in the Pilbara of Western Australia. The purchase order was raised in April 2016 for the supply of 150 linear metres of fully assembled EMS conveyor skirts. The job was manufactured, assembled and dispatched by the end of June 2016 and installed by November 2016.

Not long after the initial enquiry from MMG, an enquiry came from Perseus Mining who also needed a solution for their troublesome transfers at Edikan gold mine in Ghana. A much simpler approval process followed as the client knew exactly which style of H & B conveyor skirt was needed to do the job. It was decided to incorporate a standard design EMS conveyor skirt previously used in the Pilbara of Western Australia. The purchase order was raised in April 2016 for the supply of 150 linear metres of fully assembled EMS conveyor skirts. The job was manufactured, assembled and dispatched by the end of June 2016 and installed by November 2016.

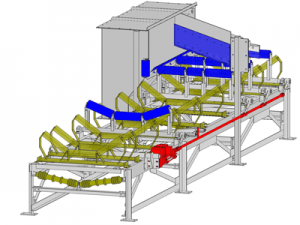

Finally, after years of overseas interest, an overseas client put pen to paper to sign off on the design and supply of a conveyor module which included an installed H & B Mining diversion plough. Belgium based company Vigan Engineering placed the order in June 2016 for a diversion plough designed to suit a 1400mm wide belt to be incorporated onto existing conveyor BC01 at Ust Luga port terminal, Russia. The plough was being employed to divert and stockpile fertiliser. All equipment was manufactured in accordance with IEC1241 zone 22 minimum with a T4 temperature rating.

The 9 metre long diversion plough conveyor module was manufactured and assembled by the end of November 2016. Factory testing was completed during the first week of December 2016 after which the module was packed into a forty foot sea container ready for dispatch. The sea container complete with the dismantled conveyor module and diversion plough components were Russia bound by mid-December 2016.

As 2016 comes to an end, H & B Mining have received further international enquiries.

If you would like more information about H & B Mining’s innovative products for conveyor transfer points contact us on (08) 9403 2993 or info@handbmining.com.au.

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au