THE MISSING PIECE IN OPTIMAL CONVEYOR TRANSFER DESIGN – FOUND

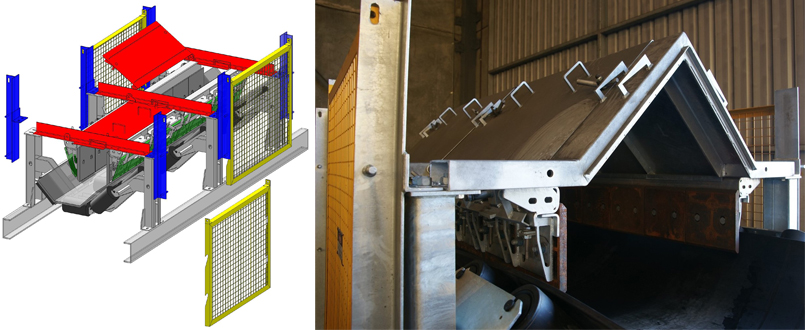

H & B Mining have developed the Streamline conveyor transfer design, with enhanced conveyor productivity in mind, promising minimal conveyor spillage, reduced shutdown time and effective accessibility for maintenance.

The unique feature of the streamline design is that it utilises the drop down idler end bracket to support the skirts, covers and guards thus eliminating the need for any intermediate support posts giving 100% access for inspection and maintenance.

The ‘Streamline’ conveyor transfer design adopts a modular style design making the products identical and the benefits many. Recording, re-ordering and storing the products is simpler; installation and replacement is quicker and easier; ultimate access to all products for safe and speedy maintenance is achieved. The design of the Streamline conveyor transfer allows for installation in any existing or new mining conveyor transfer point.

The ‘Streamline’ design really was the missing piece to the jigsaw puzzle. Eddy Hodgkinson, Managing Director of H & B stated when discussing the recent development and successful installation of the Streamline conveyor transfer design. we have now come full circle to find the perfect solution for access and maintenance at all conveyor transfer design.

H & B Mining have established themselves as specialists in conveyor transfer points. The Big Fouriron-ore miners use H & Bs drop down conveyor idlers, easy maintenance skirts, eco-light skirt liners, hinged dust covers and DILO conveyor guards as standard products on their mines. The Streamline is expected to follow suit.

The Streamline conveyor transfer design is protected by Australian Patent.

HOW TO ACHIEVE CLEAR & SAFE ACCESSFOR CONVEYOR TRANSFER MAINTENANCE

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au