MINING SITE CONVEYOR INSPECTION

MINING SITE CONVEYOR INSPECTION

With over 35 years experience, the H & B Mining’s in-house design team have a wealth of knowledge in projects that involve upgrading existing plant work. Site inspection, measuring and recording existing data for a new design is an area that H & B specialise in. Whilst obtaining and recording the as-built condition of the existing plant, H & B’s specialists discuss the proposed new design with the on site maintenance staff to ensure all the specific needs of a project are met as well as provide innovative solutions to problematic transfer areas requiring heavy maintenance.

From these discussions and recorded data the in-house design team prepare the proposed drawings for the client to review.

ON SITE MAINTENANCE PLANNING

EXAMPLE: Typical Sitework Job by H & B Mining

Listed and documented below are the four typical stages involved for all jobs or contracts requiring retrieval of site data.

STAGE 1 – SITE TRIP

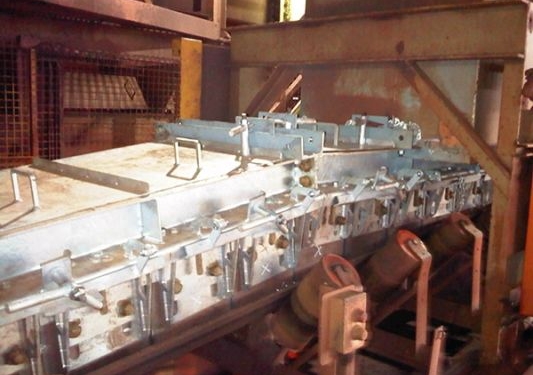

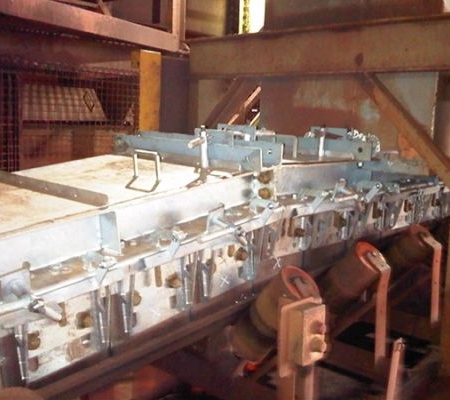

- Visit the area and inspect and photograph for record purposes

- Check the area for any potential design and maintenance issues

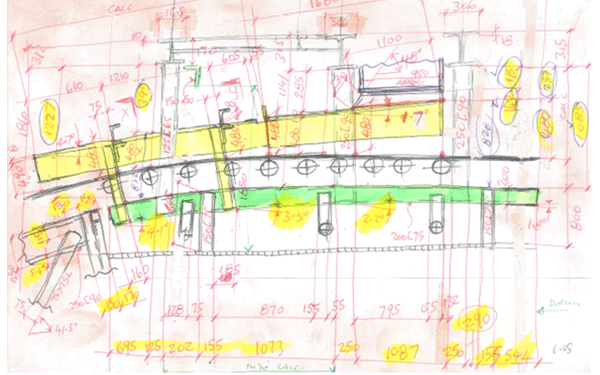

- Site sketch in preparation for site measuring existing equipment and steelwork

- Site measure and add all relevant dimensions to sketches (see below)

STAGE 2 – DESIGN

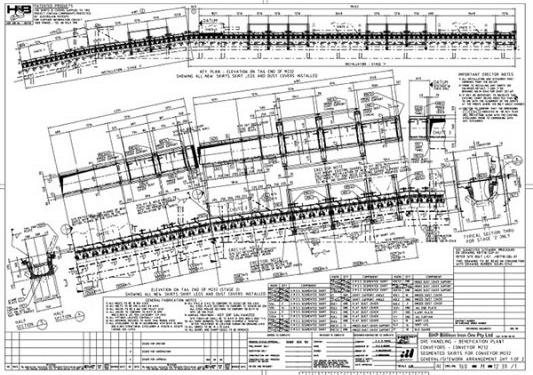

- Utilise the data retrieved from site to prepare a CAD file of the existing arrangement

- Overlay new design onto the existing arrangement ensuring that improvements to access maintenance and safety are all optimized

- Prepare design drawings

STAGE 3 – SHOP DETAIL AND FABRICATION

- Internal shop detail drawings are prepared and issued into the workshop for fabrication

STAGE 4 – INSTALLATION

- All goods are delivered to site

- The old components are dismantled and removed

- The new components are installed

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au