THE STORY OF THE H & B DIVERSION PLOUGH

The H & B Mining diversion plough has been successfully installed and operated in over 50 mine sites across Western Australia and is now entering the international market. So how did H & B Mining, a specialist design and supply company for mining conveyor transfer points become the ‘go to’ for conveyor diversion ploughs in WA and soon the world?

The H & B Mining diversion plough has been successfully installed and operated in over 50 mine sites across Western Australia and is now entering the international market. So how did H & B Mining, a specialist design and supply company for mining conveyor transfer points become the ‘go to’ for conveyor diversion ploughs in WA and soon the world?

In 2002, H & B were approached by a client with an existing problematic flatbed plough design and were keen to consider an alternative diversion plough design. After on-site assessment, the H & B design team developed the integrated diversion plough.

Over the next 5 years, the diversion plough design was improved to include the capability to activate the plough electronically or hydraulically, as well as manually.

The big mining companies in Western Australia, Rio Tinto, BHP and FMG have each separately implemented the H & B Mining integrated diversion plough. Initial implementations have been followed up with sequential orders following the success.

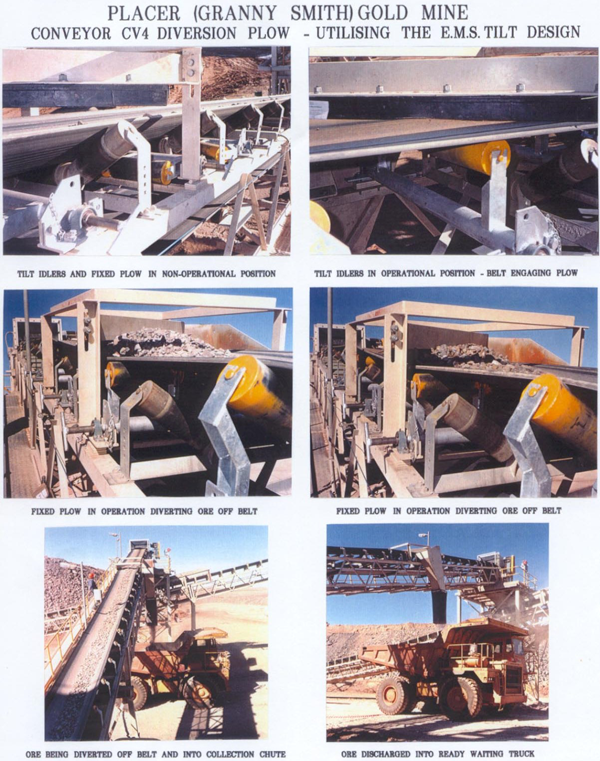

H & B Mining design and fabricate diversion ploughs to create a secondary circuit on any fixed mining conveyor. The activated diversion plough diverts material off the carry belt. A tilt idler mechanism lays dormant beneath the operational conveyor which when rotated into an operational position, raises the conveyor belt to create a flat surface to engage with a fixed diverter plate.

PLACER (GRANNY SMITH) GOLD MINE

VIDEO: CONVEYOR BELT DIVERSION PLOUGH YANDI

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au