H & B MINING GO INTERNATIONAL IN 2016

The overall success of the H & B Mining diversion plough caught the attention of VIGAN, an integrated engineering company based in Europe. VIGAN, known for providing pneumatic & mechanical conveying systems for bulk material handling plants made enquiries regarding the inclusion of such a product for their Ust-Luga Baltic Fertiliser Terminal (Phase 3) in Russia.

VIGAN were keen to incorporate H & B Mining’s diversion plough on conveyor BC28 in the new flat store distribution gantry at the fertiliser terminal. A keen client with a  short lead time forced H & B’s hand which resulted in a flight to the UK for urgent discussions in mid-August.

short lead time forced H & B’s hand which resulted in a flight to the UK for urgent discussions in mid-August.

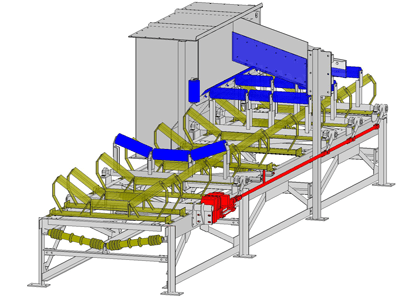

Positive negotiations resulted in a contract being awarded to H & B Mining for the design and supply of a 9m conveyor module fitted with a diversion plough for the Russian fertiliser terminal. The 9 metre long diversion plough module will replace a section of the existing conveyor currently comprised of three 3m long bays.

The diversion plough creates a secondary circuit where material can be diverted off the carry belt and into a transfer chute mounted on the stringers. The tilt idler mechanism lies dormant underneath the operational conveyor belt which when required can be activated and raised into an operational position. The raised tilt idler offers a flattened conveyor belt which when engaged with a fixed diverter plate diverts the bulk material off the belt.

H & B Mining have now completed the design phase and fabrication of the conveyor diversion plough is underway. The fully assembled conveyor diversion plough module is scheduled for completion on 30th November 2016 ready for shipment to Russia.

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au