H & B CONVEYOR SKIRTS FOR KINSEVERE COPPER MINE

H & B Mining’s reputation for supplying easy maintenance segmented conveyor skirts attracted the attention of MMG Limited. Melbourne headquartered MMG Limited operate and develop copper, zinc and other base metals projects across Australia, the Democratic Republic of the Congo, Laos and Peru.

MMG Improvement Engineers were searching for solutions to prevent carry belt longitudinal rips and rapid edge wear. After preliminary discussions and design proposals the MMG team opted for the H & B segmented conveyor skirt design to solve their belt wear and skirting issues at multiple conveyor transfer points.

“This is a bold step by the MMG team,” H & B Mining’s managing director Eddy Hodgkinson said. “It can only enhance the overall productivity of the conveyor transfer points at the world-class MMG Kinsevere copper mine.”

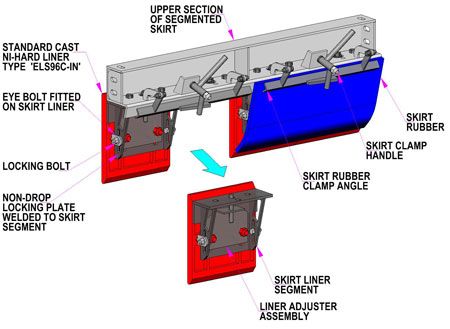

The ‘Easy Maintenance’ segmented conveyor skirting system can be custom designed to suit client’s requirements. The key design point of the H & B segmented skirt is the removable segment to which skirt liners attach. The detachable skirt segments allow for a single operator inspect and change out worn or damaged conveyor skirt liners safely within a matter of minutes from outside of the skirted area. The segmented skirt utilises a skirt rubber clamping system and provides for an adjustable gap between the primary skirt liners and the conveyor belt while also offering an adjustable secondary rubber seal.

H & B’s segmented skirts include their brand new innovative lead in liner. The design will dramatically reduce spillage; allow for simple safe and speedy maintenance and ultimately enhance the overall productivity of the conveyor transfers.

MMG Limited Kinsevere copper mine placed their first Purchase Order for H & B segmented skirts in July 2016.

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au