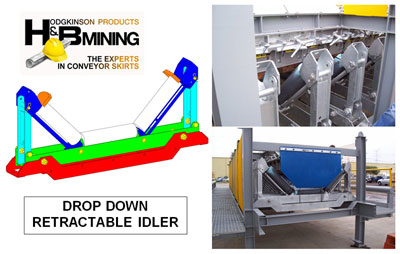

NEWLANDS COAL BUYS INTO H & B MINING’S DROP DOWN RETRACTABLE IDLER DESIGN

H & B Mining revolutionised impact idler design in the early 1990’s with the in Drop down retractable idler template image production of the ‘Drop Down Idler’ for mining conveyors.

The effectiveness of the H & B drop down idler design resulted in its inclusion as standard design for conveyor transfer points across the Pilbara of Western Australia.

The drop down conveyor idler offered mines the ability to change out worn or broken rollers in a matter of minutes, saving the mines valuable shut down time and millions of dollars. However, whilst this innovative design allowed easy access to wing rollers, it did not enable safe and easy access to the central roller.

Acknowledging this failing in its original design, the H & B in-house design team stepped up to the plate and developed the DDRI – ‘Drop Down Retractable Idler’. The DDRI has been designed to allow easy access to change out the central roller in addition to the wing rollers.

Initially selling over 2000 DDRI’s to Rio Tinto Cape Lambert Port A and Port B, H & B Mining’s drop down retractable idlers are now heading to northern Queensland. Glencore Newlands Coal has ordered 10 DDRI units to trial with a view to ordering more for both their 1800mm wide and 1200mm wide conveyor belts.

Initially selling over 2000 DDRI’s to Rio Tinto Cape Lambert Port A and Port B, H & B Mining’s drop down retractable idlers are now heading to northern Queensland. Glencore Newlands Coal has ordered 10 DDRI units to trial with a view to ordering more for both their 1800mm wide and 1200mm wide conveyor belts.

The trial ‘Drop Down Retractable Idler’ units have been dispatched to Queensland and await installation. For more information go to www.handbmining.com.au

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au