Conveyor skirting systems in high impact transfer areas are notorious for excessive skirt wear and belt tear potential, contributing to excessive material spillage and high maintenance costs.

A deliverable in conveyor maintenance has arrived!

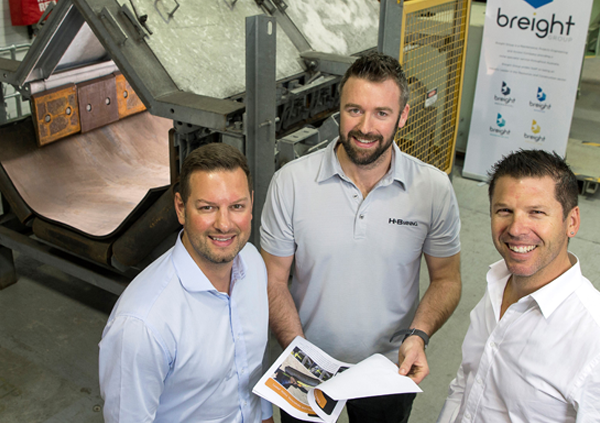

Customised H & B conveyor transfer products have coupled with educated and competent people in maintenance and standardised conveyor practices in a new collaboration between H & B Mining and Breight Group.

Conveyor skirting system design faces the challenge of forming a seal between the carry belt and skirt liner for the containment of material and dust without creating excessive friction wear to the carry belt itself.

H & B Mining have established themselves as innovators in conveyor transfer design through successful design and application of their mining conveyor products in mine-sites around the world over the last 25 years.

Ninety nine percent of mining conveyor transfer points experience the problem of skirt liner dislodgement. H & B Mining’s patented non-drop conveyor skirt liner has been identified as the solution to this problem for a West Australian iron-ore mine.

H & B’s brand new ͚Easy Maintenance Retractable Idler͛, the EMRI will revolutionise conveyor idler roller maintenance.

For over 20 years H & B Mining have been supplying their ‘Easy Maintenance’ conveyor products to the iron-ore industry of Western Australia.

H&B Mining have just started an Instagram account. We will be posting images of our innovative conveyor solutions and projects.

H & B Mining have developed the Streamline conveyor transfer design, with enhanced conveyor productivity in mind, promising minimal conveyor spillage, reduced shutdown time and effective accessibility for maintenance.

The H & B Mining diversion plough has been successfully installed and operated in over 50 mine sites across Western Australia and is now entering the international market.