PILBARA IRON-ORE INVEST IN H & B’S NON-DROP SKIRT LINER

Ninety nine percent of mining conveyor transfer points experience the problem of skirt liner dislodgement. H & B Mining’s patented non-drop conveyor skirt liner has been identified as the solution to this problem for a West Australian iron-ore mine.

Well-designed conveyor skirting systems are imperative for material containment at transfer points. Poor adherence to skirt liner maintenance (resulting from poor design) can result in skirt liner dislodgement. A dislodged skirt liner falling onto the conveyor belt can cause belt tears and damage to the machinery and equipment within the conveyor circuit, ultimately leading to millions of dollars of down time, belt replacement and equipment repairs.

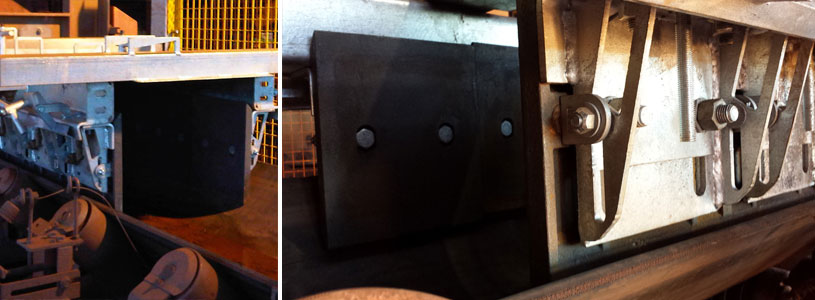

The H and B ‘Non-drop Skirt’ incorporates a custom designed skirt liner (to mining standards) that incorporates two lugs which are fitted to the liner to provide a locking interface. The skirt liner can be installed without the lugs. Either way the skirt liner will function as a normal conveyor skirt liner. The receiving locking interface on the skirt panel utilises two stiffener plates with slots to which the lugs can be fixed with locking bolts.

This innovative conveyor skirt design has the potential to be incorporated on new and old mine sites throughout Australia.

Go to the H & B Mining website for more images and information: Non-drop Conveyor Skirt Liner

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au