ULTRASEAL’ SKIRTS THE ULTIMATE SOLUTION FOR EASY CONVEYOR MAINTENANCE

Conveyor skirting systems in high impact transfer areas are notorious for excessive skirt wear and belt tear potential, contributing to excessive material spillage and high maintenance costs.

H & B Mining were recently consulted about a lump stacker conveyor transfer upgrade where skirt liner adjustment was completed every 12-13 weeks due to excessive skirt liner wear, excessive spillage resulting, belt replacement required and conveyor transfer upgrade required (time period).

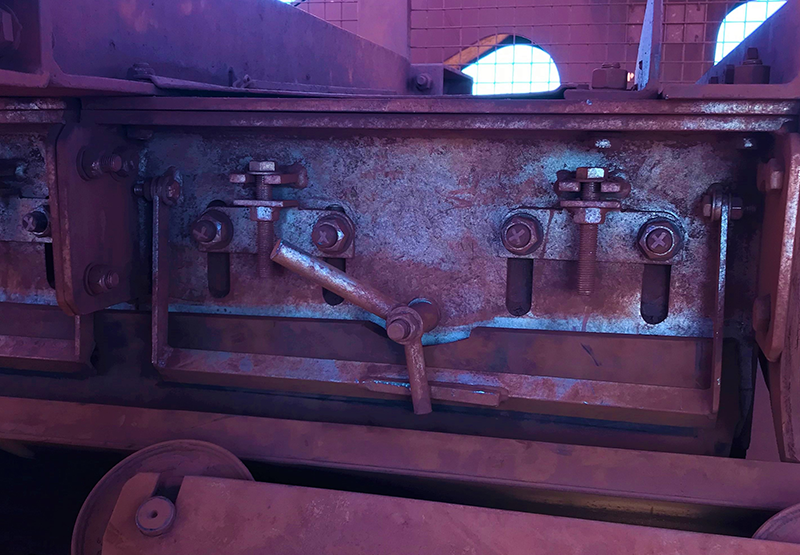

Following site inspection H & B’s design team identified ‘Ultraseal’ conveyor skirts combined with Arcoplate skirt liners as the solution.

The ‘Ultraseal’ Skirt design optimises the skirt liner to skirt rubber interface by changing the external shape of the skirt rubber. By changing the external shape of the skirt rubber, the gap between the skirt liner and the skirt rubber is eliminated and material is unable to gather and cause belt friction, thus protecting the belt from damage. With iron-ore material in mind, Arcoplate skirt liners were the perfect combination.

Arcoplate liners are a wear resistant fused alloy steel designed to resist abrasion and material hang up and so reduced friction and wear. The H & B ‘Ultraseal’ skirt design combine together to provide an easy maintenance conveyor skirt solution.

The ‘Ultraseal’ Skirt was successfully installed in June 2019. Routine skirt liner check was scheduled 13 weeks after installation as per previous skirt maintenance requirements. Maintenance crew found there was no spillage at the transfer point and there was no need for liner adjustment as there had been no liner wear.

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au