INTERNATIONAL INQUIRIES FOR DIVERSION PLOUGH AFTER FMG SUCCESS

Mining conveyor diversion ploughs are a specialised field in conveyor design – H & B Mining are establishing themselves as experts in this area.

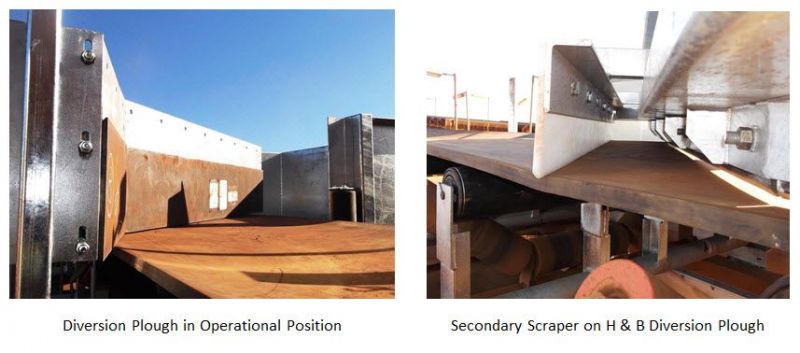

Late 2015 saw the successful installation of the H & B diversion plough for FMG on two conveyor systems at Christmas Creek, Western Australia. The diversion plough design incorporated a primary and secondary blade to ensure all bulk material was diverted from the belt.

Early 2016 has seen the fabrication of the soon to be installed diversion plough for BHP Billiton’s Jimblebar Stage 2, which follows on from the successful installation of the diversion plough in Jimblebar Stage 1.

“We are very pleased with the successful utilisation of the H & B diversion plough in WA,” stated Eddy Hodgkinson, Managing Director of H & B Mining. “H & B have been involved in the design and supply of carry-belt diversion ploughs since 1995 and we refine our conveyor diversion plough design for each conveyor as needed. We can now offer a manually, hydraulically or electrically operated systems.”

H & B Mining are now receiving inquiries from Indonesia and interstate following on from their local success. Any bulk material conveyor system that requires a secondary circuit to divert material to another conveyor, stockpile or bin can utilise a diversion plough. H & B Mining boast vast experience in this specialised area.

Go to www.handbmining.com.au or phone (08) 9403 2993.

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au