RIO TINTO EMBRACE H & B IDEOLOGY

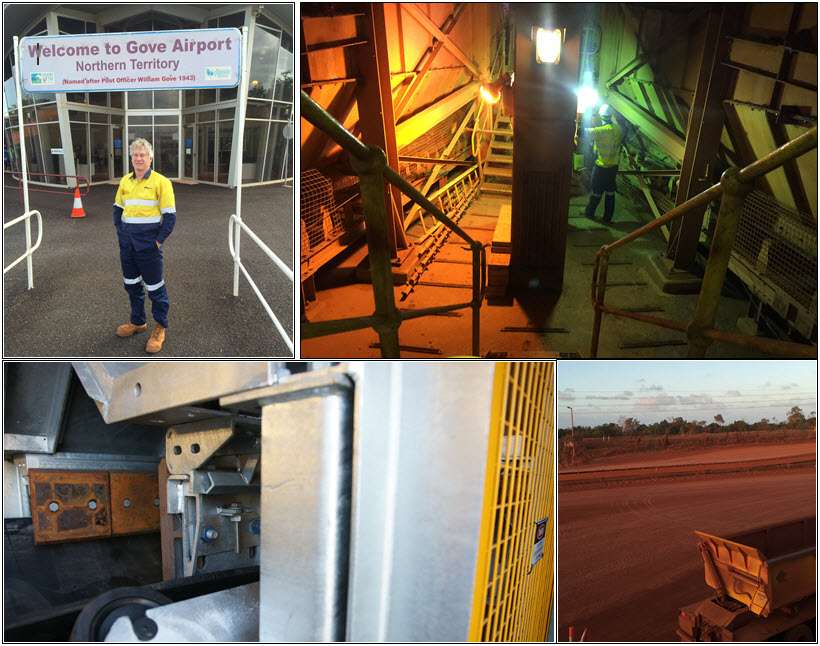

Rio Tinto Alcan has employed H & B Mining as part of the redesign for conveyor transfer points at their Gove Operations bauxite mine in the Northern Territory. After years of serious spillage and maintenance issues Rio Tinto have decided to embrace the ‘Easy Maintenance’ philosophy behind H & B’s conveyor transfer products at their bauxite operations in Gove. This follows on from successful implementation of H & B Mining conveyor products at Rio Tinto iron-ore operations in the Pilbara of Western Australia.

The H & B segmented conveyor skirt and conveyor drop down idler combination will be designed and fabricated by H & B as part of the conveyor transfer upgrade. Combining the H & B ‘Easy Maintenance’ segmented conveyor skirt together with the H & B drop down idler has proven successful across iron-ore operations in Western Australia over the past 10 years. This conveyor-skirt-idler combination has been adopted as standard design by BHP Billiton, Rio Tinto, Roy Hill and Fortescue Metals Group.

Following a visit to the H & B Mining workshop to inspect the ‘life-size’ conveyor product model, H & B’s specialist team made two site inspection trips to Gove and the decision was made to go with H & B Mining.

“This will be a lengthy project as there are 30 conveyor transfers to scan and measure, but the H & B team enjoy a challenge and can’t wait to get the ball rolling,” said Eddy Hodgkinson of H & B Mining after being awarded the Rio Tinto Alcan contract. “Inclusion of the segmented conveyor skirts and H & B idlers will clean up the conveyor transfer points and reduce shut down time down to an absolute minimum, resulting in massive financial savings”.

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au