H&B SUCCESS FOR BAUXITE CONVEYOR TRANSFERS IN NORTHERN AUSTRALIA

H & B Mining have been identified as the Experts in Conveyor Skirts for a problematic conveyor transfer point at the Rio Tinto bauxite operation on the Gove Peninsula in the Northern Territory. Rio Tinto Gove produced 6,528,000 million tonnes of bauxite in 2014; the conveyor transfer points move a large volume of material.

Good conveyor skirt design combined with a consistent conveyor belt line is paramount to keep spillage to an absolute minimum and productivity high at any conveyor transfer point.

Good conveyor skirt design combined with a consistent conveyor belt line is paramount to keep spillage to an absolute minimum and productivity high at any conveyor transfer point.

Recommended by the Maintenance Superintendent at Rio Tinto Gove, H & B Mining was taken to task to solve ongoing stacker transfer problem. The transfer point had major material spillage and conveyor belt wear problems, so much so that the belt was being changed out on a monthly basis.

The H & B site team travelled to Gove to inspect the job firsthand and identify the problems leading to excessive spillage and belt wear. The tail driven belt was being jammed beneath the existing primary skirting system causing the belt to buckle, creating an inconsistent belt line, resulting in massive spillage and belt wear.

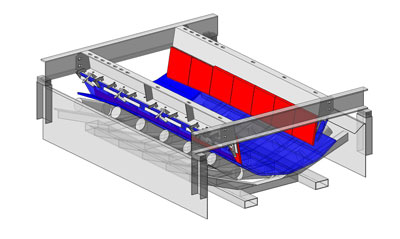

The solution was an easy fix by incorporating the H & B Easy Maintenance segmented conveyor skirts. EMS skirts provide for an adjustable gap between the primary skirt liners and the conveyor belt while also offering an adjustable secondary rubber seal.

Within a 6 week turnaround the job was designed, manufactured, dispatched and installed. The results speak for themselves with zero spillage and minor wear on the belt.

Go to www.handbmining.com.au or phone (08) 9403 2993.

Gove Bauxite Conveyor Transfer Skirts 214

Gove Alcan BEFORE Segmented Conveyor Skirts 2

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au