Segmented Ultraseal Conveyor Skirt Arrives in WA’s Pilbara

The H & B “Segmented Ultra-Seal” conveyor skirt has made an immediate impact in WA’s Pilbara. The Segmented Ultra-seal Skirt design combines all of the easy-maintenance features of the H & B Segmented Conveyor Skirt and Ultra-seal skirting system, to produce a conveyor skirt that minimises spillage, improves maintenance and prolongs the life of the carry belt and skirt liners.

A lithium mine in WA’s Pilbara contacted H & B to provide a potential solution to solve the spillage and maintenance issues they were experiencing on their existing skirting system. H & B’s expert site-inspection team completed an on-site inspection at the next available shutdown to measure up and identify design requirements.

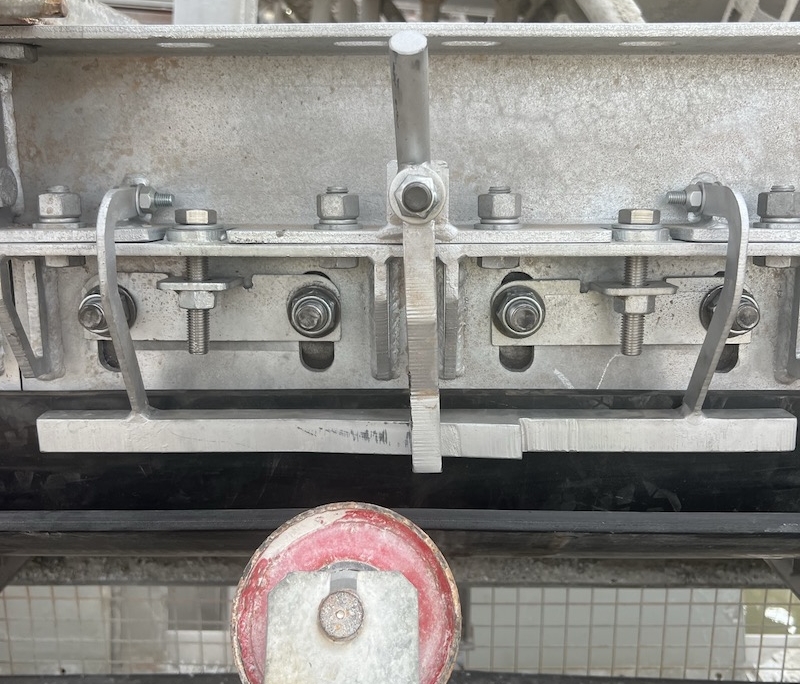

The Segmented Ultraseal conveyor skirting was identified as the best solution. The segmented skirt panel allows for access to skirt liners for liner change-out without having to climb on the belt. The ultra-seal skirt includes a step design in the secondary seal which closes the gap between the primary seal and the front face of the skirt panel, creating the best secondary sealing system on the market. The Ultraseal skirt design extends the life of the conveyor belt by preventing premature wear and grooving. In addition this skirt design includes a smart clamp to hold the ultra-seal soft skirt in place.

The in-house design team worked fast and the design was ready, fabricated and delivered to site ready for the following shutdown where H & B staff supported the successful installation of the segmented ultra-seal skirting system.

H & B Mining have pushed the boundaries yet again, producing the brand new Segmented Ultra-Seal Skirt to provide the best conveyor skirt for material containment and overall conveyor productivity.

Get in touch now for more information info@handbmining.com.au

Video Showcase

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au