CONVEYOR TRANSFER DESIGN

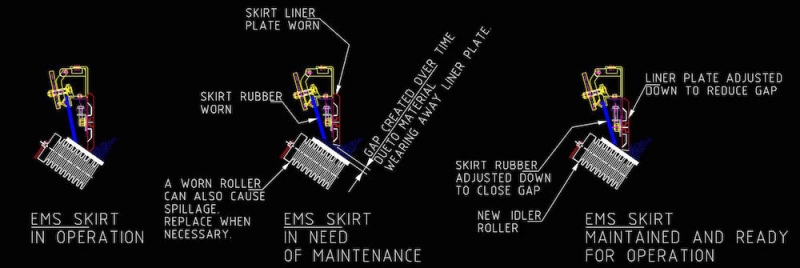

H & B Mining’s in-house design team designs conveyor transfer points to allow for easy accessibility to maximize maintenance and realise true operational benefits. An effective seal between the conveyor skirt and belt line is paramount for successful conveyor material containment. The ‘Easy Maintenance’ conveyor skirt utilises an adjustable skirt liner together with a dynamic skirt rubber design to prevent material spillage. When the ‘Easy Maintenance’ conveyor skirt is incorporated with the drop down idler, conveyor maintenance is enhanced and material spillage is reduced to an absolute minimum.

CONVEYOR MAINTENANCE

Easy and safe access to all conveyor parts that require maintenance is key to minimising material spillage. Easy access to and maintenance of conveyor idlers and rollers will result in a consistent belt line. Simple and fast adjustability of conveyor skirts will result in a lasting effective seal between conveyor belt and skirt. Conveyor products that are easy to maintain will encourage maintenance teams to carry out the maintenance tasks needed to keep conveyor transfers clean and operational.

LATEST DESIGN DEVELOPMENT

The ultimate in conveyor transfer design utilizing H&B’s easy maintenance products has been developed to improve operations, reduce shut down time and encourage maintenance. The ‘STREAMLINE CONVEYOR TRANSFER DESIGN’ has been developed to make design, supply, installation, accessibility, maintenance and replacement issues simpler, safer and quicker. Visit ‘STREAMLINE CONVEYOR TRANSFER DESIGN’ on the H&B website.

The most common area on a mining conveyor system where spillage can occur is the conveyor transfer point. Material spillage not only means loss of conveyed material but it can also result in higher maintenance costs, greater conveyor downtime and compromised safety.

CAUSE OF MATERIAL SPILLAGE AT CONVEYOR TRANSFER AREAS

The cause of excessive spillage at any conveyor transfer point is generally down to poor design. With over 30 years’ experience in conveyor transfer design H & B Mining’s approach to solving the problem of excessive material spillage is to examine three main issues:

1. BELT LINE: a consistent conveyor belt line is essential in the skirted area to maintain a seal with the conveyor skirt liners.

2. DESIGN: include products that allow for simple, safe, speedy maintenance to the conveyor skirts, idlers and rollers.

3. MAINTENANCE: easy access and easy maintainability to the conveyor skirt liners, skirt rubber and idler rolls will enhance regular maintenance.

CONVEYOR BELT LINE

A consistent belt line is needed for an effective seal to be created between the conveyor belt and skirt. The two main causes of an inconsistent belt line are belt sag and worn or damaged rollers. To guarantee a true belt line on any conveyor transfer point it is recommended that drop down conveyor idlers be incorporated into the conveyor transfer design.

H & B drop down conveyor idlers offer an extremely maintenance friendly method of changing out worn ordamaged rollers. One roller can be changed out by a single operator in a matter of minutes. Additionally, the drop down conveyor idlers are designed so that the rollers and idlers can be positioned close enough together to prevent any possibility of conveyor belt sag.

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au