NON-DROP SKIRT LINER DESIGN FOR CONVEYORS

BREAKTHROUGH AT BHP BILLITON

The introduction of the innovational modular skirt, hinged cover and DILO guarding system for Conveyor M232 at Mt Whaleback has been hailed a revelation.

Over 90 metres of old skirting on the convex curved conveyor has been replaced with the revolutionary H&B ‘Segmented Skirt’ which incorporates the new ‘Non-drop Skirt Liner’ design.

What seemed like an impossible task due to the lack of ‘as built drawings’, was completed on the 15th July, 2013.

The out-dated, patched up skirt design was falling apart and needed replacing. The existing system, as shown above, was a maintenance nightmare and a safety hazard when changing out skirt rubber and skirt liners.

The installation of H and B Mining’s ‘Segmented Skirt’ design allows skirt liners to be changed out from outside of the skirted area thus eliminating ‘confined space’ issues. The H&B segmented easy maintenance skirting system allows for skirt liners to be safely changed out in a matter of minutes, reducing shut down time and enhancing the overall productivity of the conveyor. An additional bonus to the segmented skirt design was the inclusion of the H&B ‘Non-drop Skirt Liner’ (pictured below).

This provides an additional safety mechanism within the skirting system, eliminating the chance of skirt liners becoming dislodged and falling into the material flow. Such a mishap can cause millions of dollars damage to equipment and many hours of unnecessary shut down time.

The newly installed skirting system is held in place covered and guarded with H & B’s easy maintenance modular design for conveyor belts as pictured below.

EASIER MAINTENANCE: H & B’S MODULAR DESIGN FOR CONVEYORS

H&B’s modular design ensures that all components are identical making on-site installation and maintenance simpler, safer and quicker.

IMPROVED ACCESS: Skirt legs double up as guard posts and dust cover supports thus maximizing access to all skirts and impact idlers for maintenance.

USER FRIENDLY CONVEYOR GUARDS: The DILO Guards (drop in lift out) fit between the skirt legs and have a maximum mass of 15kg whilst at the same time offering a very sturdy safety barrier. The identical guards make life easy for the maintenance crews when having to re-install the guards at the end of the shut.

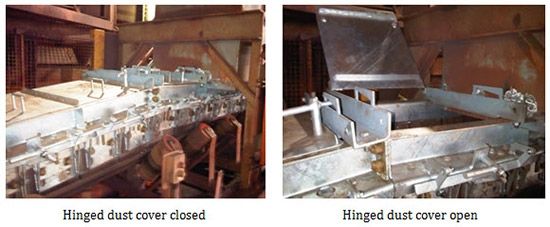

EASY ACCESS TO THE CONVEYOR BELT: H & B’s hinged dust cover system adds the finishing touch to the modular design. The hinged dust cover not only provides a labyrinth seal between covers and skirts keeping dust emissions down to an absolute minimum, it can also be opened manually in a matter of seconds offering immediate access to the conveyor belt.

Latest News

WORKSHOP

7 41 Division Street,Welshpool,

Perth, Western Australia 6106

- Tel: 08 9403 2993

- info@handbmining.com.au

HEAD OFFICE

7 Tahiti Lane, Hillarys, Perth, Western Australia 6025

- Tel: 08 9403 2993

- info@handbmining.com.au